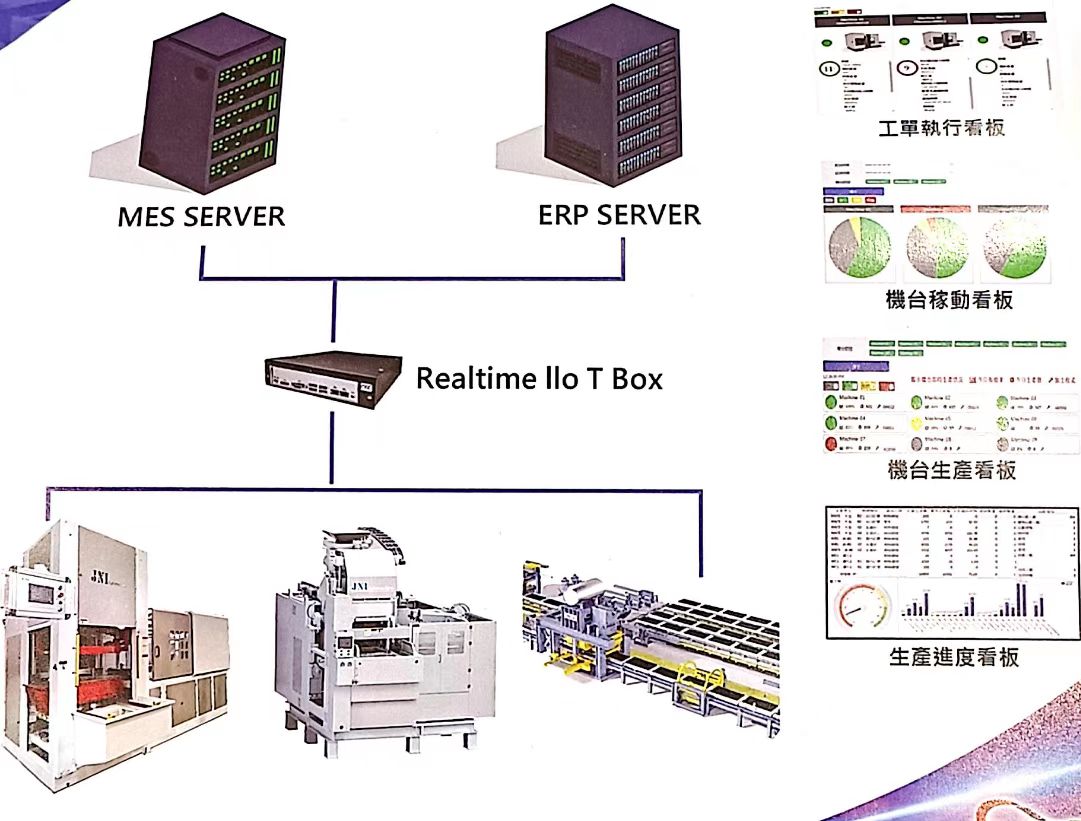

In a automation companies, the hardness Industry 4.0 remote monitoring of castings and molding machines can achieve real-time monitoring and remote control of the production process, with the following advantages:

1. Real-time monitoring: Through sensors and data acquisition equipment, the hardness information of castings and molding machines can be monitored in real time, including hardness values, curve changes, etc.

2. Remote control: Through network connection and remote control system, casting and forming machines can be remotely operated and adjusted to improve production efficiency and flexibility.

3. Data analysis: The collected hardness data can be analyzed in real time and history, and the process parameters and product quality can be predicted by algorithms and models to provide more accurate control strategies and decision support.

4. Fault warning: By monitoring and analyzing the hardness data of castings and molding machines, abnormal conditions and fault signs can be found in time, and measure can be taken in advance to avoid downtime and reduce losses.

5. Quality traceability: Through the remote monitoring system, the hardness data of each casting can be recorded and tracked to achieve quality traceability and traceability, providing support for quality management and quality certification.

Through Hardness Industry 4.0 remote monitoring, automation companies can achieve accurate monitoring and control of the production process of castings and molding machines, improving production efficiency, product quality and process optimization capabilities.

Post time: Nov-20-2023