JNJZ Automatic Pouring Machine

Features

1. Servo control casting ladle tilt at the same time, up and down and forward and backward movement of three-axis linkage, can realize synchronous casting position accuracy. Ensure the safety of operators, can greatly improve the casting accuracy and finished product rate.

2. High precision weighing sensor ensures the casting weight control of each mold molten iron.

3. After hot metal is added to the ladle, press the automatic operation button, and the sand mold memory function of the casting machine will automatically and accurately run to the place where the sand mold can be poured which is farthest away from the molding machine and has not been poured, and automatically cast the quasi-gate.

4. After the completion of each casting sand mold, it will automatically run to the next casting sand mold to continue casting.

5. Automatically skip the pre-marked non-casting sand mold.

6. The servo-controlled small screw feeding mechanism is used to control the stepless adjustment of the inoculant synchronous feeding amount, so as to realize the inoculant function with molten iron.

Mold and Pouring

| TYPE | JNJZ-1 | JNJZ-2 | JNJZ-3 |

| Ladle capacity | 450-650kg | 700-900kg | 1000-1250kg |

| Molding speed | 25s/mode | 30s/mode | 30s/mode |

| Casting time | <13s | <18s | <18s |

| Pouring control | The weight is controlled by the weighing sensor in real time | ||

| Pouring speed | 2-10kg/s | 2-12kg/s | 2-12kg/s |

| Driving mode | Servo+variable frequency driving | ||

Factory Image

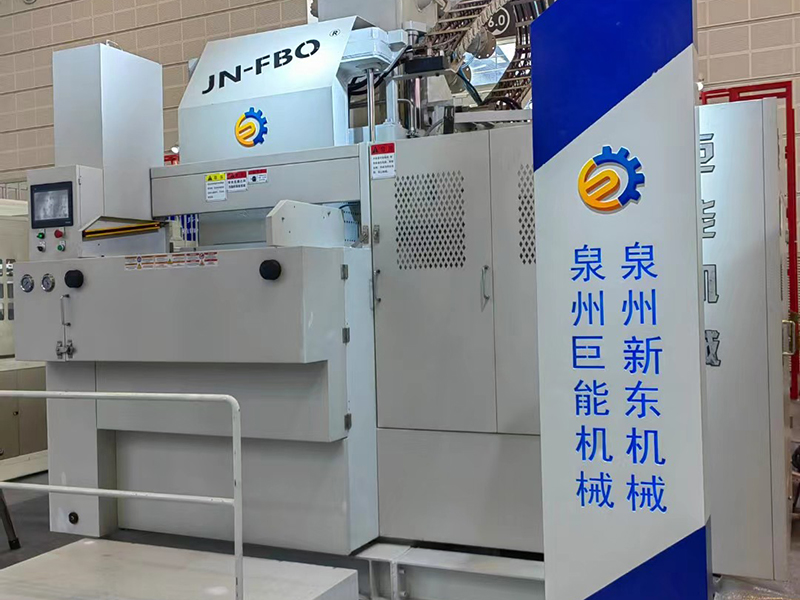

Automatic Pouring Machine

JN-FBO Vertical Sand Shooting, Molding and Horizontal Parting out of Box Molding Machine

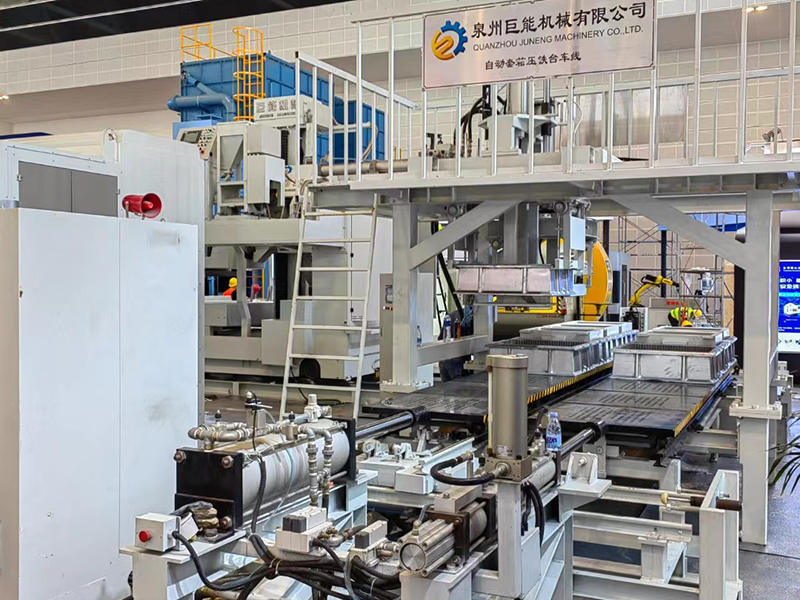

Molding Line

Servo Top and Bottom Shooting Sand Molding Machine

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.