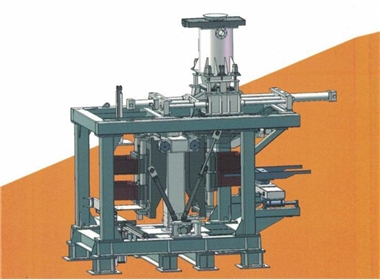

(Double standing sandblasting horizontal parting machine) is a type of equipment used in the casting industry. It is an automatic molding machine used to make castings of iron, steel, aluminum and other metal materials.

The device has the following features:

1. Dual standing design: The equipment has two workstations, which can simultaneously carry out mold filling, compaction, mortar injection and other process steps to improve production efficiency.

2. Sandblasting technology: The equipment adopts sandblasting technology, which can evenly spray the mortar into the mold to form the required casting shape.

3. Horizontal parting: The equipment adopts the horizontal parting method to complete the demoulding and cooling process of the casting through the opening and closing of the mold.

4. Automatic operation: The equipment is equipped with automatic control system, which can realize the automatic operation of the entire production process, and has the function of fault diagnosis and alarm.

The double standing sandblasting horizontal parting machine is widely used in the casting industry and can produce castings of various types and sizes, suitable for foundry and casting production needs of all sizes.

Double station sand shooting machine has the following advantages:

1. Improve production efficiency: the dual-station design enables the equipment to carry out mold filling and pouring, mold opening and taking out operations at the same time, which greatly improves production efficiency. At the same time of pouring in one station, the other station can prepare the mold, which realizes the continuous production and high efficiency.

2. Save labor cost: Due to the double station design, compared with the traditional single station sand shooting machine, the double station sand shooting machine requires less labor participation. One operator can control the operation of two stations at the same time, reducing labor costs.

3. Precise control of casting quality: The double station sand injection molding machine is equipped with advanced automatic control system, which can accurately control the temperature, pressure, sand injection speed and other parameters to ensure the stable quality of each casting. This precise control capability helps to reduce casting defects and improve product qualification rate.

4. Adapt to complex casting production: The dual-station sand shooting molding machine uses sand core and sand mold to manufacture castings, which has the characteristics of strong adaptability. It can manufacture a variety of complex shapes, precision castings to meet the needs of different industries.

5. Easy and safe operation: The design of the double station sand shooting machine takes into account the convenience and safety of the operator. The operation interface of the equipment is simple and clear, easy to master and operate, and safety devices are provided to ensure the personal safety of the operator.

To sum up, the double-station sand shooting machine has become an important equipment in the casting industry with its high efficiency, accuracy and stability, and is widely used in the production of various complex castings.

Post time: Oct-24-2023