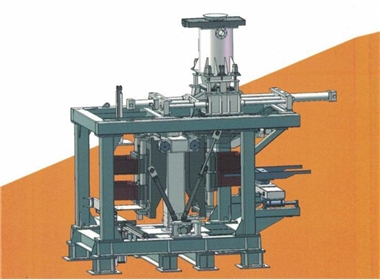

(Ob chav sawv sandblasting kab rov tav parting tshuab) yog ib hom khoom siv hauv kev lag luam casting.Nws yog lub tshuab moulding tsis siv neeg siv los ua cov hlau, hlau, txhuas thiab lwm yam ntaub ntawv hlau.

Cov cuab yeej muaj cov yam ntxwv hauv qab no:

1. Dual Standing tsim: Cov cuab yeej muaj ob qhov chaw ua haujlwm, uas tuaj yeem ua tiav cov pwm puv, kev cog lus, kev txhaj tshuaj mortar thiab lwm yam txheej txheem los txhim kho kev tsim khoom.

2. Sandblasting thev naus laus zis: Cov cuab yeej siv tshuab sandblasting, uas tuaj yeem sib npaug ntawm cov tshuaj khib rau hauv pwm los tsim cov qauv tsim nyog.

3. Kab rov tav parting: Cov cuab yeej siv txoj kev sib faib kab rov tav los ua kom tiav cov txheej txheem demoulding thiab txias ntawm cov casting los ntawm kev qhib thiab kaw ntawm pwm.

4. Kev ua haujlwm tsis siv neeg: Cov cuab yeej tau nruab nrog kev tswj hwm tsis siv neeg, uas tuaj yeem paub txog kev ua haujlwm tsis siv neeg ntawm tag nrho cov txheej txheem tsim khoom, thiab muaj kev ua haujlwm ntawm kev kuaj mob thiab lub tswb.

Ob chav sawv ntsug sandblasting kab rov tav parting tshuab yog dav siv nyob rau hauv kev lag luam casting thiab tuaj yeem tsim castings ntawm ntau hom thiab ntau thiab tsawg, haum rau foundry thiab casting ntau lawm xav tau ntawm txhua qhov ntau thiab tsawg.

Ob chav chaw nres tsheb xuab zeb shooting tshuab muaj cov hauv qab no zoo:

1. Txhim kho kev ua haujlwm zoo: qhov chaw tsim khoom dual-chaw nres tsheb tso cai rau cov khoom siv los ua cov pwm puv thiab nchuav, pwm qhib thiab ua haujlwm rau tib lub sijhawm, uas zoo heev txhim kho kev tsim khoom.Nyob rau tib lub sij hawm ntawm pouring nyob rau hauv ib qho chaw nres tsheb, lwm qhov chaw nres tsheb tuaj yeem npaj cov pwm, uas paub txog cov khoom siv tas mus li thiab kev ua haujlwm siab.

2. Txuag tus nqi zog: Vim yog ob lub chaw nres tsheb tsim, piv nrog cov tsoos ib qho chaw nres tsheb xuab zeb tua tshuab, ob lub chaw nres tsheb xuab zeb tua tshuab yuav tsum muaj kev koom tes tsawg dua.Ib tus neeg ua haujlwm tuaj yeem tswj xyuas kev ua haujlwm ntawm ob lub chaw nres tsheb tib lub sijhawm, txo cov nqi zog.

3. Precise tswj ntawm casting zoo: Ob chav chaw nres tsheb xuab zeb txhaj molding tshuab yog nruab nrog advanced tsis siv neeg tswj system, uas muaj peev xwm tswj tau qhov kub, siab, xuab zeb txhaj ceev thiab lwm yam tsis zoo los xyuas kom meej qhov ruaj khov zoo ntawm txhua casting.Qhov kev tswj xyuas meej no pab txo qis qhov tsis xws luag thiab txhim kho cov khoom tsim nyog tus nqi.

4. Kho kom yooj yim casting ntau lawm: Lub dual-chaw nres tsheb xuab zeb tua molding tshuab siv xuab zeb core thiab xuab zeb pwm los tsim cov castings, uas muaj cov yam ntxwv ntawm lub zog adaptability.Nws tuaj yeem tsim ntau hom duab, precision castings kom tau raws li qhov xav tau ntawm kev lag luam sib txawv.

5. Kev ua haujlwm yooj yim thiab nyab xeeb: Kev tsim ntawm ob lub chaw nres tsheb xuab zeb tua tshuab coj mus rau hauv tus account qhov yooj yim thiab kev nyab xeeb ntawm tus neeg teb xov tooj.Lub lag luam interface ntawm cov cuab yeej yog yooj yim thiab meej, yooj yim rau tus tswv thiab khiav lag luam, thiab cov cuab yeej muaj kev nyab xeeb yog muab los xyuas kom meej tus kheej kev nyab xeeb ntawm tus neeg teb xov tooj.

Yuav kom suav tau, ob lub chaw nres tsheb xuab zeb tua tshuab tau dhau los ua cov cuab yeej tseem ceeb hauv kev lag luam casting nrog nws cov kev ua haujlwm siab, raug thiab ruaj khov, thiab tau siv dav hauv kev tsim ntau yam kev ua haujlwm.

Post lub sij hawm: Oct-24-2023